Perfect knowledge of materials and

of processing technologies makes us

a preferred supplier.

ADVANCED PRODUCTIONS

OF TECHNOLOGY

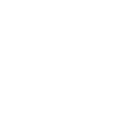

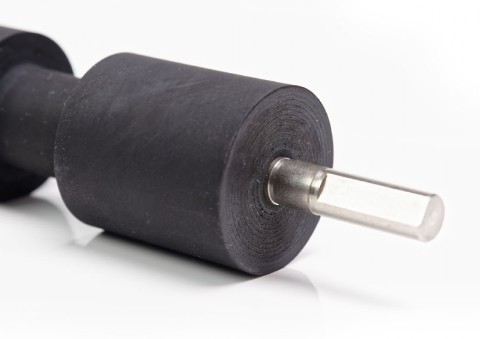

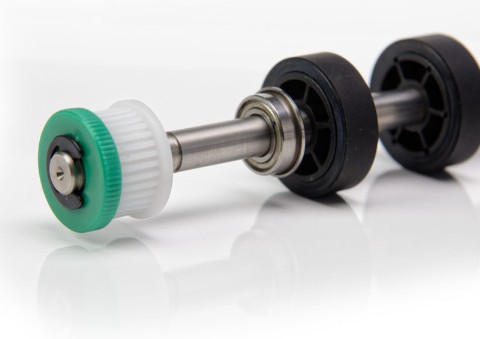

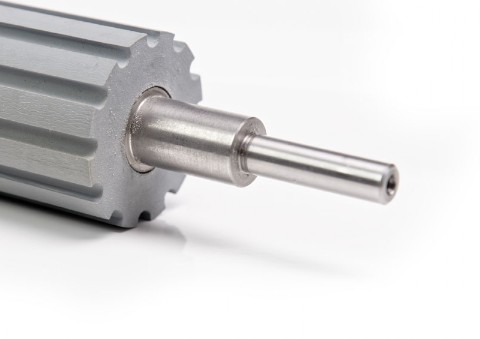

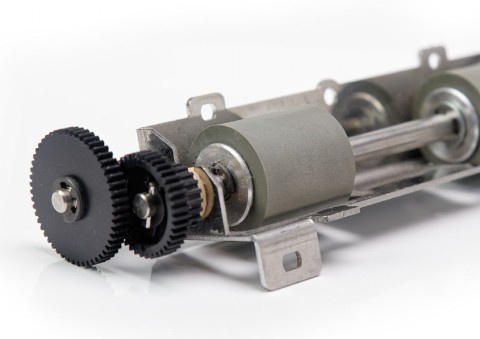

The parts we produce are destined to disparate industrial sectors such as: machinery for banking automation, paper processing machinery, various printers, machinery for office automation in general, for access control, for glass handling, for wood and other artifacts.

Our primary strength is to be able to guarantee the productivity, service and precision of the industrial reality while maintaining the flexibility and attention to detail typical of the artisan reality.

In view of this, we are able to produce even medium-small quantities, in tight deadlines. We can also offer customers a partnership aimed at the joint identification of the solution that best matches the technical, qualitative and economic requirements required in the final application, with maximum confidentiality in the transfer of sensitive information.

The decades-long experience gained allows us to provide the customer with an effective synergy in the search for cutting-edge technical and economic solutions in our specific sector.

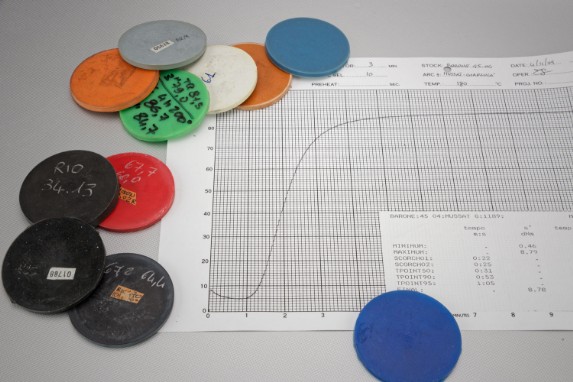

Thanks to its technicians and to a deep and updated specific knowledge we can boast the mastery of the entire production process, with particular relevance to the study and formulation of rubber compounds, considered as a key point and common denominator of all its supplies.

The possibility of processing numerous elastomeric compounds which can be customized upon request, in order to provide additional necessary features, makes our company able to operate in technologically advanced sectors, where high level performances are required. We can also manage the transformation of the compounds through different processes with considerable advantages in terms of operational flexibility and competitiveness.

The availability of machinery suitable for processing, as well as the high precision finishing of the components allows us to satisfy projectually shrinking requests.

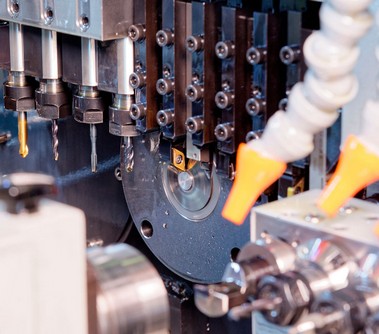

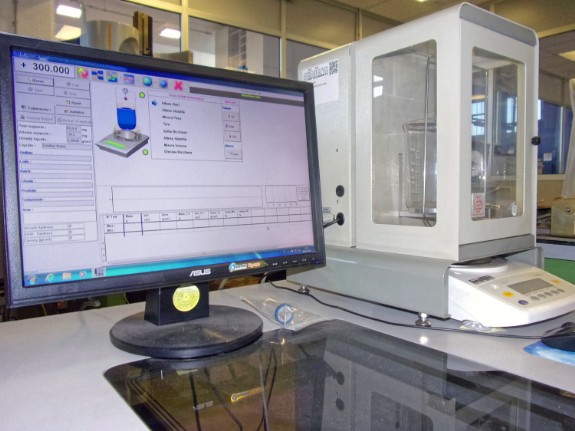

All productions are monitored by a management system for analyzing the efficiency of machinery, for planning / planning, for batch traceability, for optimizing the times / costs of production cycles.

THE ELASTOMERIC COMPONENTS

PROCESSES

FINISHING

• compounding

• compression molding

• injection moulding

• transfer molding

• extrusion

• casting materials for casting

• molecular adhesion

• molding of thermoplastic materials

• Hot air vulcanization and steam autoclave

Precision grinding with traditional machines

semi-automatic, CNC.

Some systems are equipped with automatic and robotized production islands.

MATERIALS

Treated elastomeric matrices:

- NR (natural rubber)

- NBR (acrylonitrile-butadiene)

- CR (chloroprene)

- EPDM (therpolymer of ethylene-propylene and diene)

- SBR (styrene-butadiene)

- VMQ (Silicone - silicone-rubber)

- PU Polyurethane (millable and cast polyurethane) AU - EU

THE SMALL ITEMS

TREATMENTS

MATERIALS

PROCESSING

Treatments surface / heating:

• nickel plating

• galvanizing

• anodization

• burnishing

• nitriding

• hardening

Materials worked:

Stainless steels of various degrees

aluminum

AVP

brass

copper

bronze

plastic resins

others.

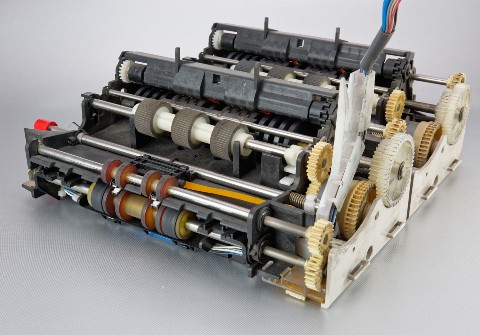

CNC sliding headstock lathes (with magazines for automatic bars) with bar passage from 2mm to 35mm diameter

Additional shooting operations:

• threading

• milling

• adjustment

• rolling

DESIGN AND CO-ENGINEERING

A TEAM OF SPECIALISTS

FOR ALL YOUR NEEDS

FOR ALL YOUR NEEDS

We have qualified staff and cutting-edge software systems to assist the customer in the design and development of new products, improvement of existing solutions and start-up of production.

In case of need, we have the possibility to perform dynamic and static tests, also thanks to the collaboration with external specialized laboratories.

SMART STOCK MANAGEMENT

Starting from a careful selection of the best raw materials and selective controls, all the compounds are carefully designed and tested for each specific use.

Precision optical and laser instruments allow non-contact measurements to be made on the finished parts, avoiding the slightest deformation of the rubber parts.

THE CONTROL INSTRUMENTS

We have a small laboratory with specialized personnel for the characterization of the compounds and able to carry out both analytical and comparative tests and analyzes for the main characteristics.

VERSATILITY ED

PRODUCTION EFFICIENCY

To ensure rapid delivery, we have integrated a large warehouse in the production plant for raw materials or components. Also, we have the possibility, also thanks to semi-automatic warehouses, to manage minimum stocks agreed with the customers in such a way as to guarantee continuity in the delivery flows of the goods.

GALLERY